ADM: DENSITY METER FOR SLURRY

The innovative, but simple and robust non-nuclear Alia Density Meter (ADM) for slurries offers accurate real-time data, allowing clients to truly optimize their production while eliminating the costs of special certifications and the disposal of hazardous materials.

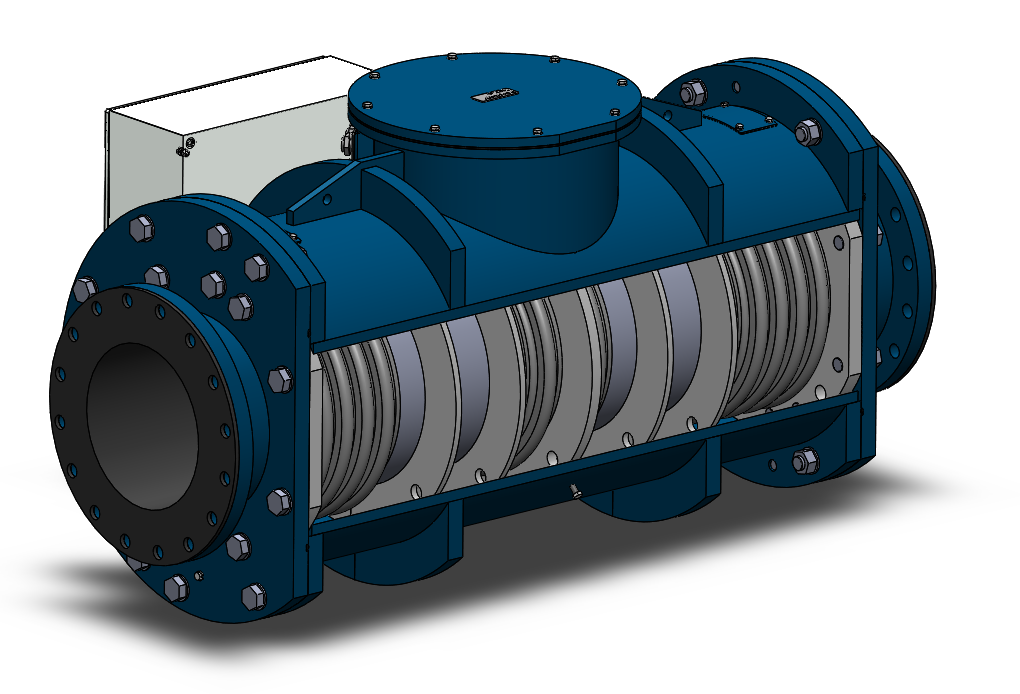

Alia Instruments is a producer of process control equipment in various markets. The Alia Density Meters (ADMs) are used for the continuous density control of different slurries in many applications. These processes are often characterized as challenging processes due to their abrasive or corrosive characteristics.

For many years, there was no option available other than using gamma radiation to measure these slurries from outside the pipe. However, with the inception of Alia Instruments, customers now have a sustainable alternative to control and optimize their processes.

ADVANTAGES OF ALIA INSTRUMENTS

- A simple, reliable, and robust product

- Easy installation; no need for external commissioning engineers

- An immediate signal, showing actual values

- Measurement of all materials—e.g., sand, metals, rocks, and gases—without any problems (incl. freshwater and saltwater)

- Easy integration with existing systems and software

ADVANTAGES OF USING A NON-NUCLEAR DENSITY METER

- A more sustainable business management and company reputation

- Employees who are not afraid to perform checks and repairs

- No need for special trainings or specifically trained personnel

- Demonstrating social responsibility, and responding to society’s pressure to reduce nuclear waste

- No concerns about more stringent regulations in the future

- No more challenges when transporting nuclear sources

OPTIMISE PRODUCTION

The density of slurries is measured to support the operator to control and enhance the production. Traditionally this is done with gamma meters. The radioactive source however is the cause of a lot of practical drawbacks with regards to licenses, training, shipment and operators who have their reservations about using such technology. Furthermore it has an impact on the business management of companies who have to answer to society’s pressure to reduce nuclear waste, and to operate in a sustainable manner. The Alia Density Meter is an electromechanical alternative without these drawbacks. It offers a quick and accurate measurement of the density of slurries. It can be easily combined, e.g. with existing flow meters and control systems.

WORKING PRINCIPLE

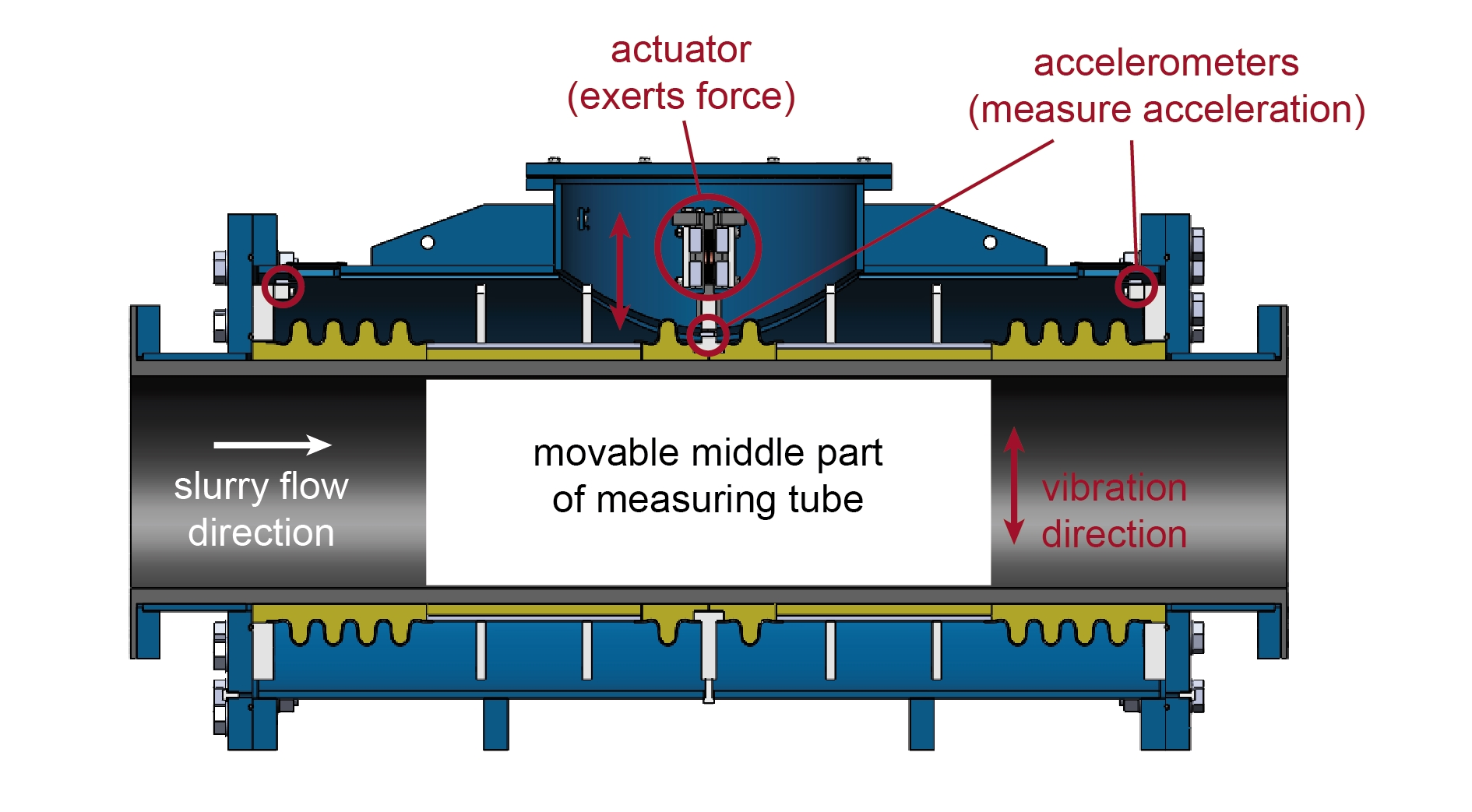

The Alia Density Meter is positioned in-line in the slurry pipeline. The density, defined as the slurry mass per volume unit, is measured under dynamic conditions , i.e. when the slurry is flowing. Inside the density meter, an actuator exerts a force with a known value and frequency onto the slurry, while an accelerometer measures its resulting acceleration. Newton’s second law of motion F = m x a, which relates the force F to the acceleration a via the mass m, is utilized to determine the mass of the slurry . The slurry volume is a known factor in the measuring tube of the meter. This means that the measured slurry density is nearly immediate and accurate, regardless of pipe diameter or slurry composition .

The central part of the density meter is the measuring tube through which the slurry flows. This tube consists of an outer part made of metal, giving stiffness to the tube, an intermediate part of polyurethane, and an inner part made of (natural or EPDM) rubber, giving flexibility to the tube. This rubber part gets in contact with the flowing slurry.

At the outer ends, near the position where the density meter is connected to the slurry pipe, the metal outer part of the measuring tube consists of bellows, allowing the middle part of the measuring tube to move in one radial direction. Rotational movement of the middle part is constrained by flexure leaf springs, and movement in other radial directions is prevented by the construction of the measurement device.

The actuator, consisting of a copper electrical coil surrounded by a permanent magnet package, exerts a force onto the measuring tube, allowing the middle part of the measuring tube to vibrate in the direction perpendicular to the slurry flow. The central accelerometer, which is positioned at the radial outer part in the middle of the measuring tube, measures the resulting acceleration of the measuring tube with the slurry flowing through.

In addition to the central accelerometer, two accelerometers are positioned near the outer ends (‘left’ and ‘right’) of the measuring tube. Besides measuring the position, velocity and acceleration at positions just adjacent to the movable middle part of the measuring tube, they also compensate for external influences to the measurement.

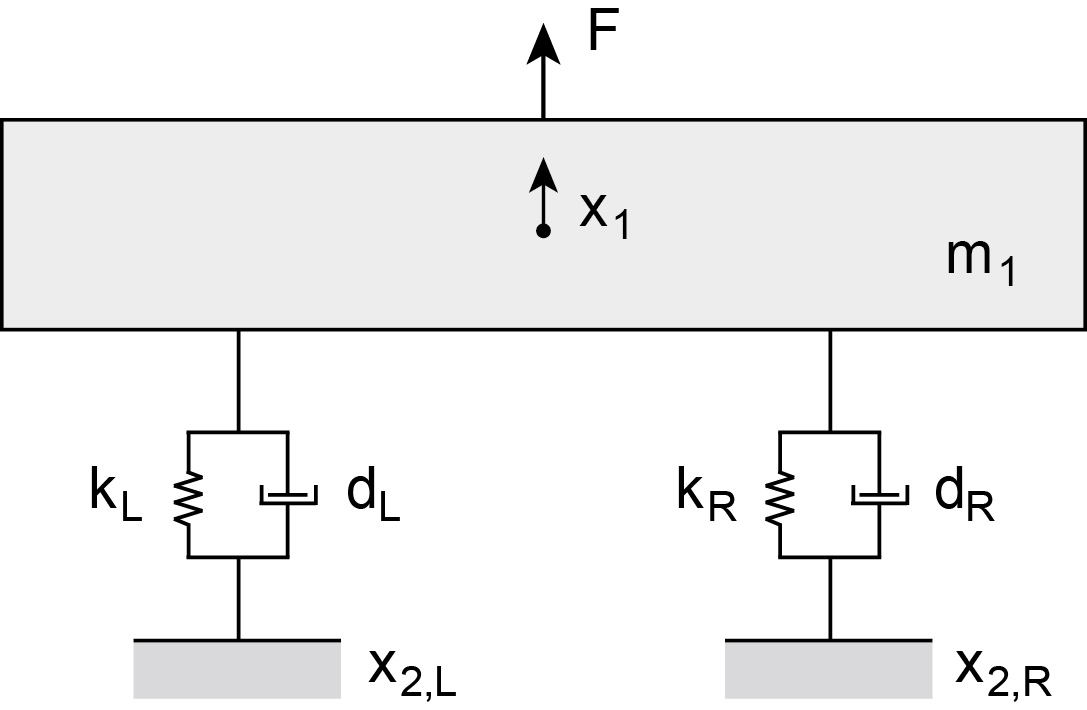

The mechanical model shows the suspended measuring tube including slurry flowing through, with mass m1 and (center of mass) position x1. L(eft) and R(ight) suspension consists of two springs with stiffness kL or kR, and dampening dL or dR.

Based on the exerted force F and the measured acceleration x”1, the mass m1 of themovable part of the measuring tube including the slurry can be calculated.

When corrected for the mass of the measuring tube itself, the mass of the relevant slurry inside this tube is known. Dividing this mass by the inner volume of the movable part of the measuring tube reveals the density of the flowing slurry inside the measuring tube.