SID 1 Machine Level Monitor of Mechanical Wear

Call for Price

SID 1 Permanent Control Loop Monitoring

- Deployment at machine level

- Designed to detect wear and tear early

- No cloud connection required

- No additional sensors required

SID 1 – Predictive Maintenance Software for Early Machine Level Wear Detection of Industrial Machines

SID 1 is a standalone predictive maintenance software that detects mechanical wear and faults by monitoring changes in control loop behaviour at machine level—without cloud connectivity or raw data storage.

SID = Smart. Industrial. Design. Mathematical certainty, not guesswork.

Product type: Software-only | On-premise | No cloud required

Book Demo / Ask QuestionsQuick Overview

➜ Application: Predictive maintenance / asset performance monitoring

➜ Technology: Inverse control loop analysis (PID-based)

➜ Deployment: On-premise software (no cloud)

➜ Compatibility: Any PLC, HMI, or Edge device

➜ Data handling: Minimal data usage (no raw data storage)

➜ Security: No external data transfer

➜ Scalability: Unlimited sites, unlimited assets

What SID 1 Actually Does

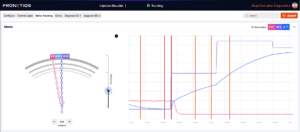

SID 1 continuously monitors the behaviour of control loops to detect early signs of mechanical wear and tear in industrial equipment. Instead of relying on vibration sensors, thresholds, or probability models, SID 1 uses a mathematical algorithm to identify changes in how machines respond over time.

When a machine begins to degrade—whether gradually, suddenly, or intermittently—its control loop behaviour changes. SID 1 detects those changes early, giving maintenance teams time to act before failures, downtime, or production losses occur.

Unlike many predictive maintenance tools, SID 1 operates entirely on-premise, with no cloud dependency and no sensitive data leaving your facility.

Key Capabilities

Inverse Control Loop Diagnostics

→ Detect mechanical wear using mathematical certainty, not indicators.

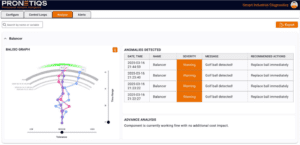

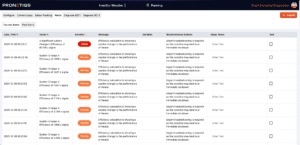

Baliso Graph Visualization

→ Instantly see deviations in Proportional, Integral, and Derivative (PID) behaviour.

Early Fault Detection

→ Identify gradual wear, oscillations, sudden faults, and transient anomalies.

Configurable Alerting

→ Set warning and critical thresholds based on your process tolerance.

Monetary Impact Visibility

→ See the cost impact of deviations to drive faster corrective action.

Cloud-Free Architecture

→ Maximum security with no external data exposure.

Universal Compatibility

→ Works with any PLC, HMI, or Edge device—vendor-agnostic by design.

Who This Is For — And Who It Isn’t

Ideal for:

- Maintenance teams seeking early detection of mechanical wear

- Plants aiming to reduce unplanned downtime

- Operations with critical control loops (movement, pressure, temperature)

- Facilities with strict data security requirements

- Multi-site operations needing scalable predictive maintenance

Not ideal if:

- You need plant-wide asset and control loop visibility from a centralized dashboard (see SID 5)

- Your focus is on mobile control loop diagnostics and process tuning without central SCADA (see SID 3)

- Your use case is centered on industrial network visibility, communication diagnostics, or security awareness (see IntraVUE)

Use Cases

Early Detection of Mechanical Wear

Identify wear and tear in control loops before it leads to failure or quality issues.

Asset Performance Monitoring

Continuously track machine health using control behaviour rather than sensors.

Preventive Maintenance Planning

Schedule maintenance activities based on real system behaviour—not assumptions.

Reduced Downtime & Cost Control

Address issues early to avoid costly shutdowns and production delays.

Multi-Site Predictive Maintenance

Deploy SID1 consistently across facilities without cloud limitations.

Technical Specifications

Technology

- Diagnostic method: Inverse control loop analysis

- Control loops supported: PID-based systems

Deployment

- Software-only solution

- No cloud connection

- On-premise installation

Data & Security

- Minimal data collection

- No raw data storage

- Restful API / HTTPS access

Compatibility

- PLCs

- HMIs

- Edge devices

- Vendor-agnostic

Availability

- 24/7 monitoring

- Continuous operation, year-round

Compatibility and Deployment

SID 1 integrates seamlessly into existing automation environments without changes to control strategies or system architecture.

- Any PLC platform

- Existing HMIs

- Edge computing devices

Deployment highlights:

- No cloud setup

- No vendor lock-in

- No process-specific binding

Documents and Downloads

![]() SID 1 Product Card (583kb)

SID 1 Product Card (583kb)

![]() Use Case – Primary and Secondary Packaging (988kb)

Use Case – Primary and Secondary Packaging (988kb)

Frequently Asked Questions

How does SID 1 detect wear without sensors?

SID 1 analyzes control loop behaviour mathematically, identifying deviations that indicate mechanical changes.

Does SID 1 require a cloud connection?

No. SID 1 operates fully on-premise with no data leaving your facility.

How quickly does SID 1 provide insights?

Once installed, results are available within minutes and update continuously.

Is SID 1 tied to specific PLC brands?

No. SID 1 is vendor-agnostic and works with any PLC or HMI.

Can SID 1 scale across multiple sites?

Yes. There is no limitation on the number of assets or locations.