Coriolis, Customers, Endress+Hauser, Notes From The Field, Problem Solving, Streamline Process Management

An Endress+Hauser Coriolis Picks Up Bad Vibrations

Lessons from the field on external noise, ghost flows, and data validation.

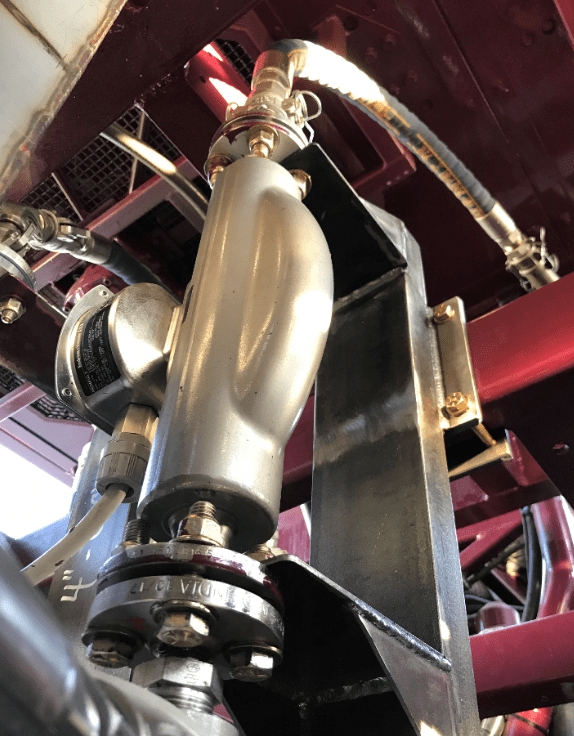

We received a call from a customer about an Endress + Hauser Coriolis meter mounted on a twin pumper testing with antifreeze. They were experiencing ghost flows. When they closed off the valves on each side of the meter (blocking in), the meter would produce ghost flows at operating RPM.

The first day was spend just getting up to speed. We inspected the installation, wiring, etc. Everything was in order.

Side note: Using flexible hose can cause ghost flows if the hose is moving. Often clamping or securing the hose can reduce this effect.

Our customer had placed rubber between the frame mounts to dampen any vibrations coming from the frame. This dramatically improved the frequency and magnitude of the ghost flow events, but they still had ghost flows.

Transmitter display vs the frequency output

Due to inherent display dampening, the transmitter display was not showing outputs that were very short. Using a multi-meter, we were able to see the short burst ghost rates at the transmitter that were reaching the guys at the HMI. I.e. did not see any issues on the transmitter display, but back in the control cab, you can see the PLC counting the frequency output.

After inspecting the configuration, I tried to modify the transmitter settings to remove the intermittent spikes on flow output. I was successful in removing the short burst outputs/ghost flows. But then when actually flowing, it had the effect of shorting the measured fluid, robbing Peter to pay Paul as it were.

I hypothesized that external vibrations were impacting the meter measurement. I needed to be able to gather data to prove or disprove this theory. I started looking for tools that might fit our requirements. Many of the tools I found online were very expensive.

In the end I used the Google Science Journal App; it turns your smart phone into a measurement device. You can record and graph accelerometer information, dB, brightness, compass, magnetometer, and pitch (Hz). I am still amazed at how much data you can get from your phone with a free app. I recorded at a few different points on the unit, ad with the unit operating at different RPM.

Measurement #1: On idle. Nothing of note, no ghosting reported.

Measurement #2: Same location as the unit ramps; fans come on full.

When the radiator operates, the 4 separate fans should all operate at the same spin. It is interesting to note the pattern on the above pitch recording. When the fans are out of phase the frequency essentially multiplies. What we see are the tiers of frequencies emitted; spikes are consistent frequencies. The ones in the +500Hz range were interesting, as this was close to the resonance frequency of the tubes with the fluid.

Frequency

The way that a Coriolis determines density is through frequency. Think of a Coriolis like a tuning fork. You add energy to the tuning fork (tap it on something) and it puts out a tone. A tuning fork created from different density materials would produce a different tone (or frequency). With the meter, the drive coil adds energy and the tubes will resonate at the natural frequency of the fluid inside. The mass flow is determined by the amount of phase shift. As per the picture below: If A + B are in phase, they would essentially overlap each other and register as zero flow. The greater the shift, the greater the mass flow through the meter.

When external frequencies are near or at the same resonance as the those observed in the meter, what happens? Those frequencies would essentially do the same as we observed with the radiator fan reading. In phase, the amplitude would build. When out of phase, they will product sporadic outputs showing ghost flows.

To prove this outside of the unit we were looking at, I had Rob back at our shop hook up a meter and using an oscilloscope apply the frequency (as indicated by the meter) to the flange. We were able to produce ghost flows with empty tubes, but not when we filled the meter up with water. The energetic output of the oscilloscope was not powerful enough to affect the measurement when the tubes were full. We did verify that external frequencies of the same resonance, would impact the measurements of the meter.

To solve the customers problem, we then needed to find another install location where we did not encounter these issues. Using the Google Science Journal App again, we took measurements at different locations on the unit to find a place least impacted by the frequencies. We did find a location. When installed and tested no ghost flows occurred. Problem solved.