SID 5 Centralized Control Loop Monitoring for Complete Asset Visibility

Call for Price(Approx. $US 0.00)

SID 5 Centralized Control Loop Monitoring

- Deployment from a central location

- Designed for facility leadership & plant managers

- Centralized insights, reports & benchmarking

- Complete overview of operations

SID 5 – Centralized Control Loop Monitoring for Complete Asset Visibility

SID 5 is a centralized industrial diagnostics software that provides a complete, real-time overview of machine health by continuously monitoring control loop behaviour across your entire operation.

Factory-wide diagnostics from a single dashboard.

Product type: Software-only | On-premise | No cloud required | No additional sensors

Book Demo / Ask QuestionsQuick Overview

➜ Application: Centralized diagnostics & asset monitoring

➜ Scope: Multi-machine, multi-loop environments

➜ Technology: Control loop behaviour analysis

➜ Data Collection: Passive via OPC-UA / MQTT

➜ Deployment: On-premise software (no cloud)

➜ Sensors Required: None

➜ Cloud Dependency: None

➜ Scalability: Factory-wide and multi-site capable

What SID 5 Actually Does

SID 5 gives maintenance and engineering teams a single, unified view of the health of all monitored machines in a facility. By continuously analyzing control loop behaviour, SID 5 detects wear, instability, and unwanted events before they escalate into downtime or production losses.

Unlike point tools or reactive alarm systems, SID 5 centralizes diagnostics across machines and control loops, allowing teams to prioritize issues, understand cost impact, and act faster. All insights are generated on-premise, without cloud connections, raw data storage, or additional sensors.

SID 5 is designed for plants that need visibility at scale, not just insight at the machine level.

Key Capabilities

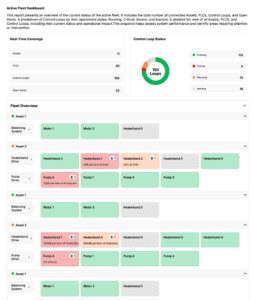

Centralized Diagnostics Dashboard

→ Monitor all machines and control loops from one interface.

Control Loop Status Overview

→ Instantly see healthy, warning, and critical loops across the plant.

Baliso Graph Visualization

→ Clearly visualize changes in Proportional, Integral, and Derivative behaviour.

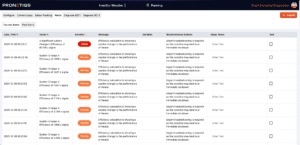

Real-Time Alerts & Prioritization

→ Identify issues early and focus on what matters most.

Cost-of-Failure Insights

→ Assign monetary impact to alerts to drive smarter decisions.

Reporting & Analytics

→ Generate asset, alert, and fleet-level reports in minutes.

Passive Data Collection

→ Gather insights via OPC-UA / MQTT with no impact on control systems.

Who This Is For — And Who It Isn’t

Ideal for:

- Facilities with multiple machines and control loops

- Maintenance teams managing plant-wide reliability

- Engineering teams seeking a unified diagnostics platform

- Plants aiming to prioritize maintenance based on risk and cost

- Operations that require secure, cloud-free diagnostics

Not ideal if:

- You only need portable, single-asset diagnostics (see SID 1)

- Your focus is strictly process efficiency tuning (see SID 3)

- You require communication network or cybersecurity diagnostics (see IntraVUE)

Use Cases

Factory-Wide Asset Monitoring

Track the health of all monitored machines from a single dashboard.

Early Detection of Wear & Instability

Identify gradual or sudden changes in control behaviour before failure.

Maintenance Prioritization

Focus resources on the machines with the highest risk or cost impact.

Operational Reporting & Oversight

Provide management with clear, data-driven insights into plant health.

Scaling Predictive Maintenance Programs

Expand diagnostics across lines, areas, and sites without adding sensors.

Technical Specifications

Technology

- Diagnostic method: Control loop behaviour analysis

- Visualization: Baliso Graph (PID gain representation)

Data & Connectivity

- Passive data collection via OPC-UA / MQTT

- No raw data storage

- Secure on-premise access

Deployment

- Software-only

- No cloud connection

- No additional sensors required

Operation

- Continuous monitoring

- Real-time alerts

- Suitable for 24/7 industrial environments

REPORTING & INSIGHTS

SID 5 includes built-in reporting tools that transform diagnostics data into actionable insights:

Asset Alert Summary

→ View all active and resolved alerts by machine.

Alert Trend Report

→ Identify recurring issues and hidden patterns over time.

Fleet Report

→ Compare performance across machines and control loops to prioritize maintenance.

These reports provide clarity for both technical teams and decision-makers.

Compatibility and Deployment

SID 5 integrates seamlessly into existing automation environments without changes to control strategies.

Compatible with:

- PLCs

- HMIs

- Edge devices

- Vendor-agnostic

Deployment advantages:

- Rapid setup

- Flexible configuration of control loops per machine

- Scales easily as operations grow

Documents, Downloads and Link

Central Monitoring of Control Loops in Large Plants

SID 5 Product BrochureFrequently Asked Questions

How is SID 5 different from SID 1?

SID 1 focuses on early detection of mechanical wear on individual assets. SID 5 provides a centralized overview across all machines and control loops.

Does SID 5 require additional sensors?

No. SID 5 passively gathers data via OPC-UA / MQTT.

Is SID 5 cloud-based?

No. SID 5 operates entirely on-premise with no cloud dependency.

How quickly does SID 5 deliver value?

Within minutes of setup, SID 5 begins providing live insights and alerts.

Can SID 5 scale across large facilities?

Yes. SID 5 is designed for factory-wide and multi-site deployments.